Other Insights

Dec 4 2025

AI at Work: How Microsoft 365 Copilot Is Moving Sales, Service, and Finance Teams to the Frontier

Sep 25 2022

What does Packaged foods, Medical/Pharma, Health Providers, Real Estate and Beverages have in common?

Need help or want to know more?

Find our contact info here

“DynamicsPrint® with IMP is the heart of our planning estimations and imposition systems.

Estimating has become an important science. Our young estimators can deliver accurate plans just as an experienced estimator, with loads of experience, would.”

Angel Viveros, Estimation Manager

Foli De Mexico, Mexico

“The reason we chose DP was because it’s an industry solution which solves many of the problems we had in the standard Microsoft Dynamics setup. Also, there was demand from the management to have final costing, which was also a major challenge in the standard Dynamics solution.

DynamicsPrint® also helps us greatly with scheduling and shop floor management. The data gathered gives us great insights, and results in a much more cost-efficient production.”

Jochem Sants, Project Manager

Van der Most, Heerde, Netherlands

“The professional and highly skilled DynamicsPrint® team led the implementation to develop the expertise internally at DCM with a team of Subject Matter Experts from each of the specialized print production areas. DynamicsPrint’s expertise regarding the system and the industry was instrumental to ensuring the configurations were done properly. As this is a highly configurable solution, the approach and implementation was very well structured and ensured that the team worked from the basic setups to the more complex setups with a pace that was manageable and retainable.

DynamicsPrint® adjusted the resource requirements to accommodate both technical and functional areas of expertise as needed throughout the project, providing best practice directives to ensure that the proper approach was being followed.”

Karen Redfern, VP Operations Technology

DCM, Canada

“I just wanted to let you know how happy I am with DynamicsPrint® and the support you have given KP San Leandro since our launch. The seemingly endless set of tools available really help us run and improve our business.

The visibility into job statuses, P&L, and the ability to create and manage cues that give our team a personalized look into their own area of responsibility have become essential to our business model. I can’t even imagine going back to our old system. Thanks to the DynamicsPrint® team for all your help and support.”

Mark Floyd, Division Director

KP Corp. San Leandro, USA

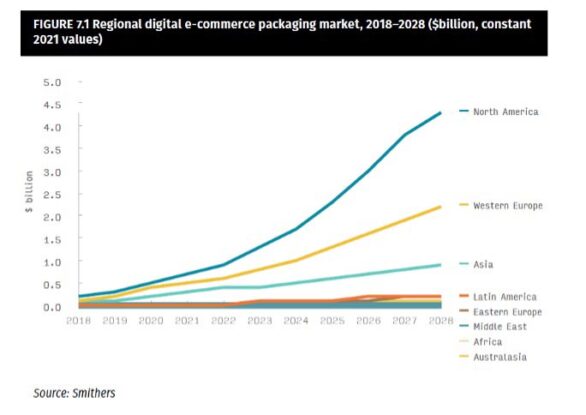

The year is 2050. What does packaging look like? Not just in its form — but in its function, materials, and impact on society. That’s the question Gillian Garside-Wight of Aura posed ahead of her presentation at London Packaging Week 2025. And it’s a question every supply chain leader, sustainability officer, and brand executive in the print and packaging sector should be asking themselves today.

From macroeconomic shifts to climate volatility, the forces reshaping packaging aren’t merely trends — they’re transformative disruptions. Aura’s foresight work outlines four compelling scenarios that envision packaging’s evolution in parallel futures: from a high-tech, AI-assisted world to one strained by resource scarcity and climate realities.

Rethinking What “Packaging” Means

In the High-Tech Future, packaging becomes smart and dynamic — capable of communicating allergen data, usage instructions, and environmental impacts through digital overlays tailored to the consumer. Imagine packaging that updates itself based on where it’s scanned or even responds to real-time feedback from the supply chain.

But this is only one path.

In a more constrained reality — what Aura dubs The Tough Alternative — resource scarcity drives materials strategy. Brands may need to pivot from choosing optimal packaging to selecting what’s available. Localized, biodegradable alternatives like seaweed and mushroom fibers could dominate. Landfill mining might become standard practice for material sourcing.

These are not science fiction scenarios. They are plausible outcomes built on today’s data.

Design Thinking Meets Systems Thinking

By 2050, it’s expected that two-thirds of the global population will reside in urban centers. With aging demographics, new governance models, and Asia’s economic leadership reshaping global supply chains, the role of packaging must go beyond aesthetics and protection. It will become a systemic enabler for equitable, sustainable consumption.

This isn’t just about innovation — it’s about resilience.

Retailers and packaging companies must consider circularity at scale: refillable systems, backhaul logistics for e-commerce, and embedded digital identities for traceability. And with regulations like Extended Producer Responsibility (EPR) tightening worldwide, tomorrow’s packaging leaders will need to design not just for shelf appeal, but for entire life cycles.

Planning for the Long Game

The packaging industry has always adapted — through material science, automation, and digital transformation. But the next horizon demands a different mindset: long-term, strategic planning with a willingness to pivot across multiple scenarios.

Garside-Wight’s challenge to the industry is clear: Stop planning for the next three years, and start preparing for the next three decades.

The future of packaging is not a singular vision — it’s a multidimensional map. The decisions made today will either limit or liberate the industry’s ability to respond to tomorrow’s crises and opportunities.

Are we ready?

Book Demo