Other Insights

Dec 4 2025

AI at Work: How Microsoft 365 Copilot Is Moving Sales, Service, and Finance Teams to the Frontier

Sep 25 2022

What does Packaged foods, Medical/Pharma, Health Providers, Real Estate and Beverages have in common?

Need help or want to know more?

Find our contact info here

“DynamicsPrint® with IMP is the heart of our planning estimations and imposition systems.

Estimating has become an important science. Our young estimators can deliver accurate plans just as an experienced estimator, with loads of experience, would.”

Angel Viveros, Estimation Manager

Foli De Mexico, Mexico

“The reason we chose DP was because it’s an industry solution which solves many of the problems we had in the standard Microsoft Dynamics setup. Also, there was demand from the management to have final costing, which was also a major challenge in the standard Dynamics solution.

DynamicsPrint® also helps us greatly with scheduling and shop floor management. The data gathered gives us great insights, and results in a much more cost-efficient production.”

Jochem Sants, Project Manager

Van der Most, Heerde, Netherlands

“The professional and highly skilled DynamicsPrint® team led the implementation to develop the expertise internally at DCM with a team of Subject Matter Experts from each of the specialized print production areas. DynamicsPrint’s expertise regarding the system and the industry was instrumental to ensuring the configurations were done properly. As this is a highly configurable solution, the approach and implementation was very well structured and ensured that the team worked from the basic setups to the more complex setups with a pace that was manageable and retainable.

DynamicsPrint® adjusted the resource requirements to accommodate both technical and functional areas of expertise as needed throughout the project, providing best practice directives to ensure that the proper approach was being followed.”

Karen Redfern, VP Operations Technology

DCM, Canada

“I just wanted to let you know how happy I am with DynamicsPrint® and the support you have given KP San Leandro since our launch. The seemingly endless set of tools available really help us run and improve our business.

The visibility into job statuses, P&L, and the ability to create and manage cues that give our team a personalized look into their own area of responsibility have become essential to our business model. I can’t even imagine going back to our old system. Thanks to the DynamicsPrint® team for all your help and support.”

Mark Floyd, Division Director

KP Corp. San Leandro, USA

The packaging floor has changed. Has yours?

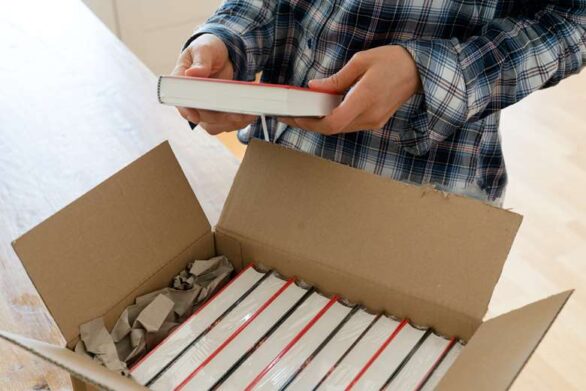

In today’s environment of rapid change and demand volatility, traditional converting operations are feeling the strain. High-volume analog workflows still deliver scale — but they often can’t keep up with the speed, customization, and responsiveness now expected by packaging buyers.

Enter digital print — not as a replacement, but as an essential complement.

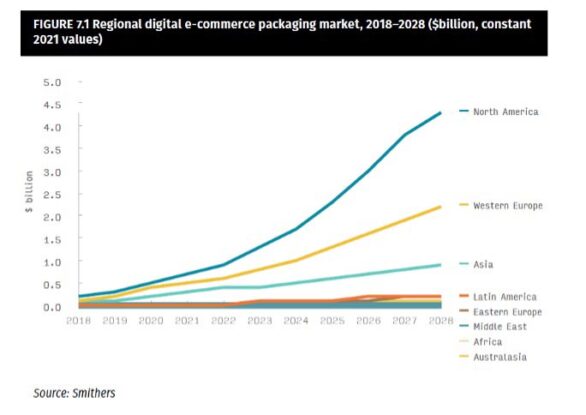

At Keypoint Intelligence, the data shows a steady progression: digital is claiming a larger share of packaging, especially in segments like folding carton and labels. The shift isn’t dramatic — but it’s strategic. The converters who lead this evolution aren’t abandoning flexo or offset; they’re adding digital as a strategic advantage.

The Reality on the Floor

Lean crews. Smaller runs. Last-minute artwork changes. Buyers now avoid over-ordering, instead opting for campaign-based production and promotional agility. For converters, this means traditional make-ready times and rigid workflows are becoming liabilities.

Digital print, with its minimal setup time and on-demand flexibility, helps converters adapt to short runs while preserving margins and avoiding delays.

Yet many still hesitate—citing complexity, uncertainty, and cost. The solution isn’t just a press. It’s a reimagined workflow, aligned with new expectations.

Why Agility Is the New Competitive Edge

Customer loyalty is no longer tied solely to quality — it’s tied to responsiveness.

As Jeff Wettersten, VP at Keypoint Intelligence, puts it:

With digital print, converters can offer test batches, fast turnarounds, and real-time personalization. This isn’t just a capability — it’s a service advantage that drives long-term customer retention.

Digital Creates New Niches — And New Margins

Smaller brands and premium product makers now demand customized, creative packaging in shorter runs. These markets were once inaccessible to analog-only converters due to setup inefficiencies.

Digital enables access to these high-value, low-volume opportunities — where converters compete on design, service, and speed, rather than price.

Why Hybrid Is the Smartest Path Forward

Contrary to popular belief, this isn’t a binary choice. Long-run analog print still delivers cost efficiencies at scale. But flexibility is where the competitive battles are now being won.

The most resilient converters are those who:

Route jobs strategically between digital and analog

Maximize throughput without overburdening crews

Reduce waste and overproduction

Align production with sustainability goals

Hybrid operations are not a compromise — they’re an optimization strategy.

Aligning with Sustainability Demands

Sustainability is no longer optional — it’s embedded in policy, procurement, and purchasing behavior.

Digital supports sustainability by reducing overproduction, minimizing inventory risk, and enabling precise run lengths that match demand. For brands, this is tangible progress. For converters, it’s a competitive differentiator.

Final Thoughts

The packaging industry is not in decline — but it is being redefined. Growth now hinges on adaptability.

The future belongs to converters who recognize that long-run efficiency and short-run agility are not in conflict — they are complementary imperatives. The hybrid model enables both.

As more buyers demand flexibility, transparency, and sustainable practices, converters that invest in digital — not just the equipment, but the operational alignment — will hold the edge.

The floor has changed. And the winners will be those who change with it.

Book Demo